Comparison of properties with various types of coated steel sheets

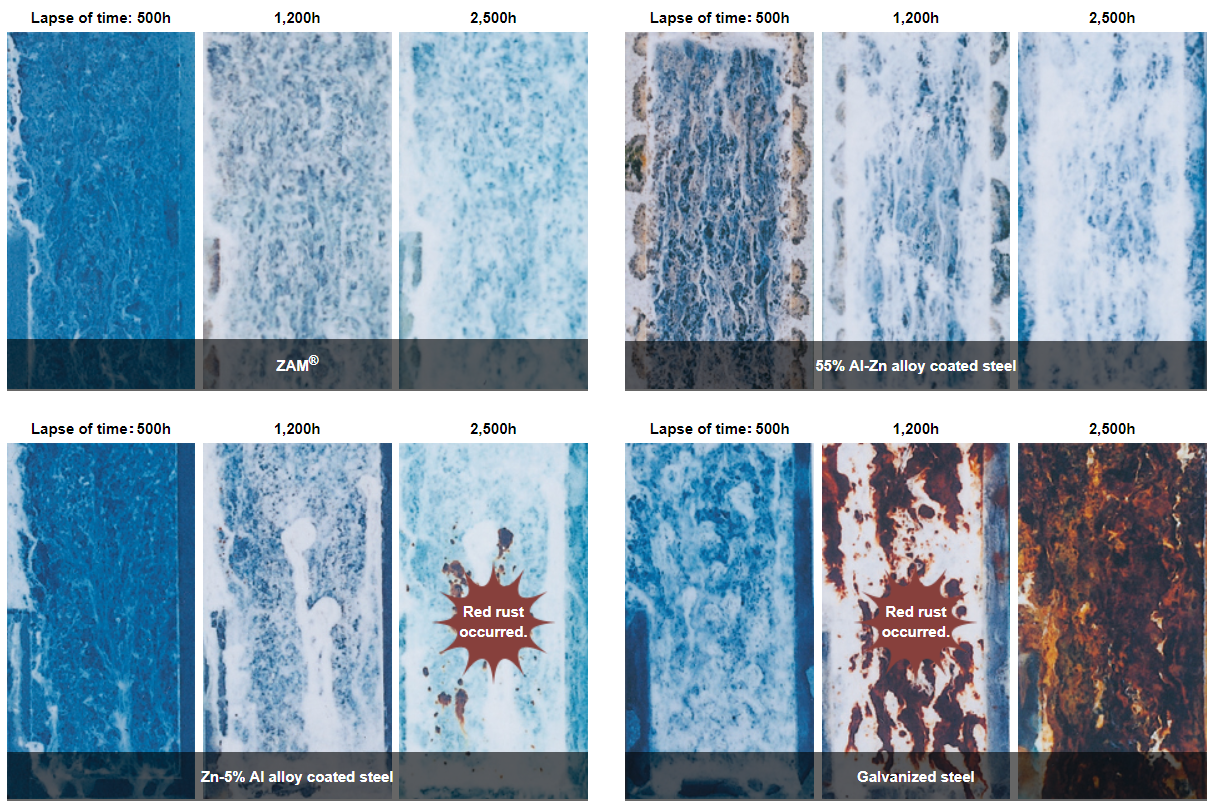

Corrosion resistance on flat parts

ZAM has better resistance to red rust than galvanized and hot-dip zinc-5% aluminum alloy coated steel sheets

Results of salt spray test (SST: JIS Z 2371) Appearances of specimens after salt spray test

(Coating weight: 90/90 g/m2, untreated)

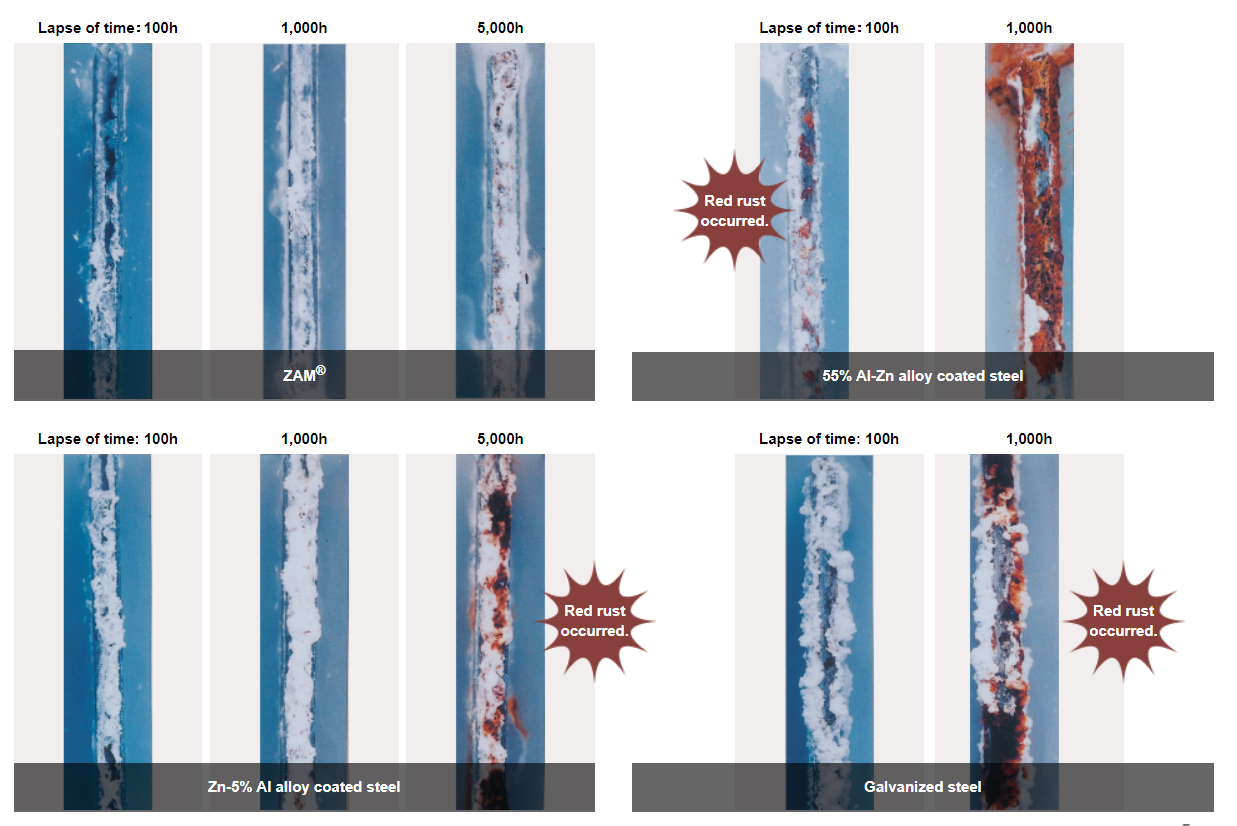

Corrosion resistance on cut edge

ZAM® shows better red-rust resistance (durability) on cut edge than any other coated steel sheet.

Appearances of cut edges after salt spray test

(Thickness: 3.2 mm, coating weight: 120/120 g/m2, untreated)

Change in the appearance of cut edge during outdoor exposure test

The cut edge of ZAM® will be covered with a protective film and change to a subdued color as time passes.

Appearances of cut edge sections after outdoor exposure test (testing location: seaside industrial area in Sakai)

(Thickness: 2.3 mm, coating weight: 90/90 g/m2, chromate treatment: 50 mg/m2)

Corrosion resistance of bent sections

Appearances of 1t bent section after salt spray test

(1t, 180º bending, thickness: 3.2 mm, 120/120 g/m2, untreated)

Change in appearance at bent section during outdoor exposure test

Corrosion resistance of drawn sections

ZAM® shows better corrosion resistance on drawn parts compared to hot-dip zinc-5% aluminum alloy coated steel sheets.

Appearances of drawn parts after salt spray test

(drawing height: 25 mm, thickness: 0.8 mm, coating weight: 70/70 g/m2, untreated)

Source: Nippon Steel

Source: Nippon Steel