The need to use cable tray ladder systems in construction projects is increasing, leading to the accompanying cable tray accessories being carefully considered when choosing. But how do know which accessories are suitable for the cable tray? What is the standard for accessories? Bestray will answer all your questions under this article.

1. What are cable tray accessories?

When it comes to Cable tray accessories, it is used to refer to types of Horizontal eblow 45o/90o, outside vertical 45o/90o, inside vertical 45o/90o, T-type, intersection, straight drop… In the standard TCVN 10688:2015 (IEC 61537):2006), Section 3.5 is referred to as “Fittings” and is defined as “System component used to join, change direction, resize or terminate cable trays or ladder segments. cable”.

Cable tray accessories are accompanying equipment, supporting the cable tray ladder to function well. The task of cable tray accessories is mainly to connect the cable tray ladders according to different shapes and pipes to match the equipment installation location.

Cable tray ladder accessories are often sold with cable tray ladders to make it easy for customers to buy a complete set of suitable cable tray ladders.

2. What are cable tray accessories used for?

Cable tray accessories usually account for about 10% ~ 30% of the order value, but play a very important role in the installation of cable tray ladder systems for projects. Besides, they support the easy redirection of the cable tray system. Avoid collisions with systems in the building when installing, reduce costs with optimal levels, and have many suitable sizes for the size of the work.

The outstanding uses of cable tray accessories are as follows:

Make a fixed and sure connection to the cable tray ladder system

● Play an important role to ensure the safety of the system during construction

● Save time and effort in construction and installation

● Save construction area and bring high convenience

● Diverse design, high load capacity, and high aesthetics for the project.

3. Classification of cable tray accessories and installation accessories:

3.1. Splice plate

A splice plate is an accessory with the use of connecting two connected cable trays, between the trough and its accompanying accessories, or between two other accessories. This accessory makes the cable trays, cable ladders more solid and secure. Currently, there are two types of cable tray connections: discrete and continuous.

Cable tray connectors include:

● Hinged vertical connector (vertical connector): used to connect cable trays vertically, customized at the construction site.

● Hinged horizontal connecting bowl (horizontal alignment bowl): an accessory that is used to connect cable trays horizontally, customized at the construction site.

● Left reduction connection (which is a noun used to refer to a reducing coupling, with a direction that goes straight to the left): with the use of reducing the size of the cable tray to the left.

● Right reduction connector (which is a noun used to refer to a reducing coupling, with a straight direction to the right): with the task of supporting the reduction of cable tray size to the right.

● Evenly reduced connector: is an accessory to connect two cable trays of different sizes. In addition, it can also be used to connect two different cable trays and accessories.

3.2. Cover

Cable tray cover (Cable Tray Cover) is used to cover the cable tray and protect the internal wiring and cables. At the same time, the trough cover also protects the conductor from insects and the impact of the external environment.

Each type of cap will have its design and standards suitable for the environment of each project. Therefore, the selection of the cover should consider the characteristics of the construction and the construction surface. In addition, the cable tray cover must have the size and shape suitable for the construction cable tray system. Normally, cable tray covers will be classified according to the material of manufacture as follows:

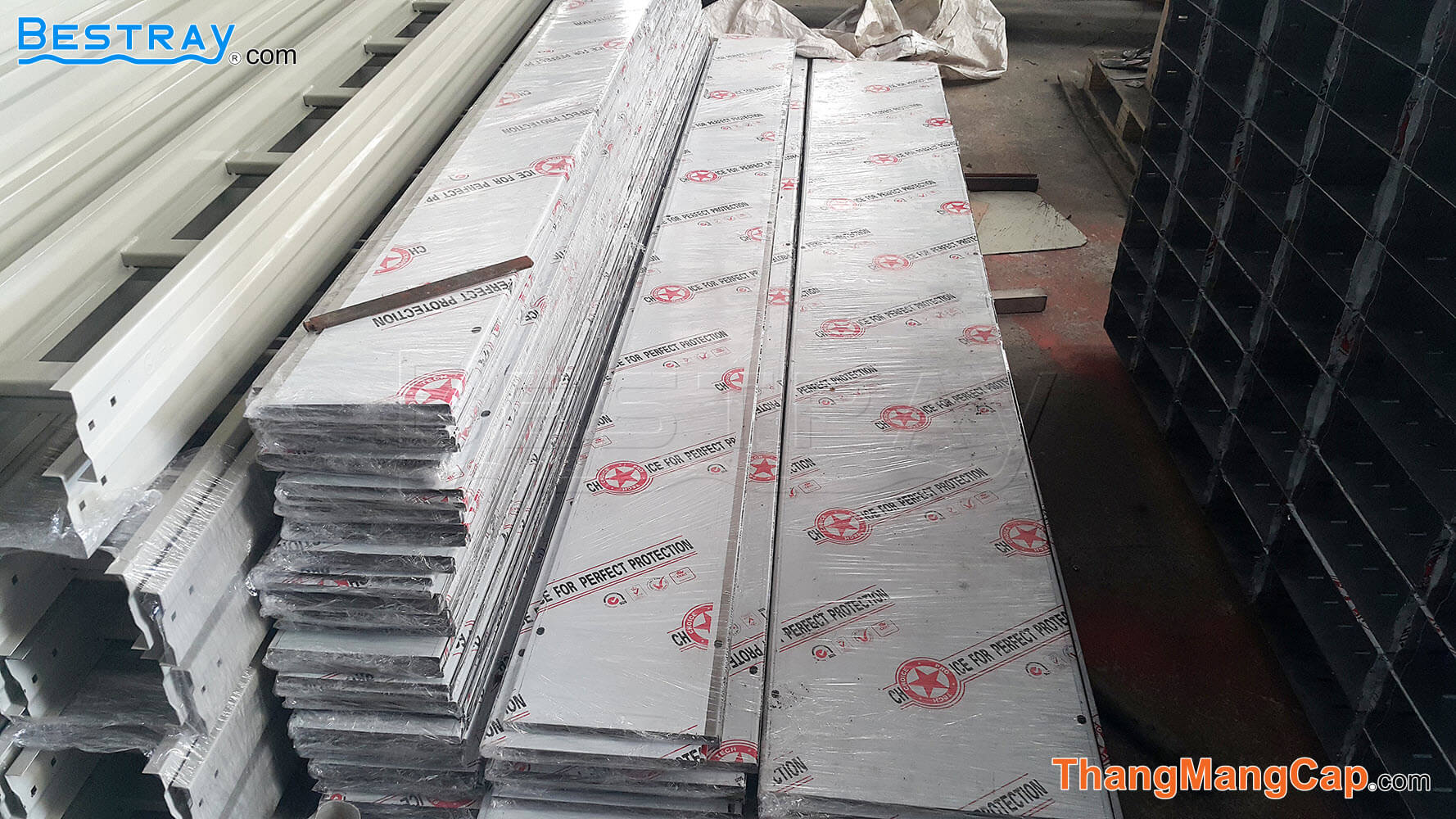

● Pre-galvanized cable tray cover (zinc corrugated iron): used for indoor installation, in dry and ventilated places. This product has the advantage of a smooth, uniform zinc color, beautiful aesthetics, resistance to all external influences such as dirt, insects… With a reasonable price, this is a line trusted by many customers. use.

● Rear galvanized cable tray cover (hot-dip galvanizing): is a line of accessories widely used in constructions, used for indoor and outdoor. They are used mainly in projects that require high technical and product characteristics. Therefore, this cable tray cover is often used for projects near the sea, chemical plants, environments with high alkalinity,…

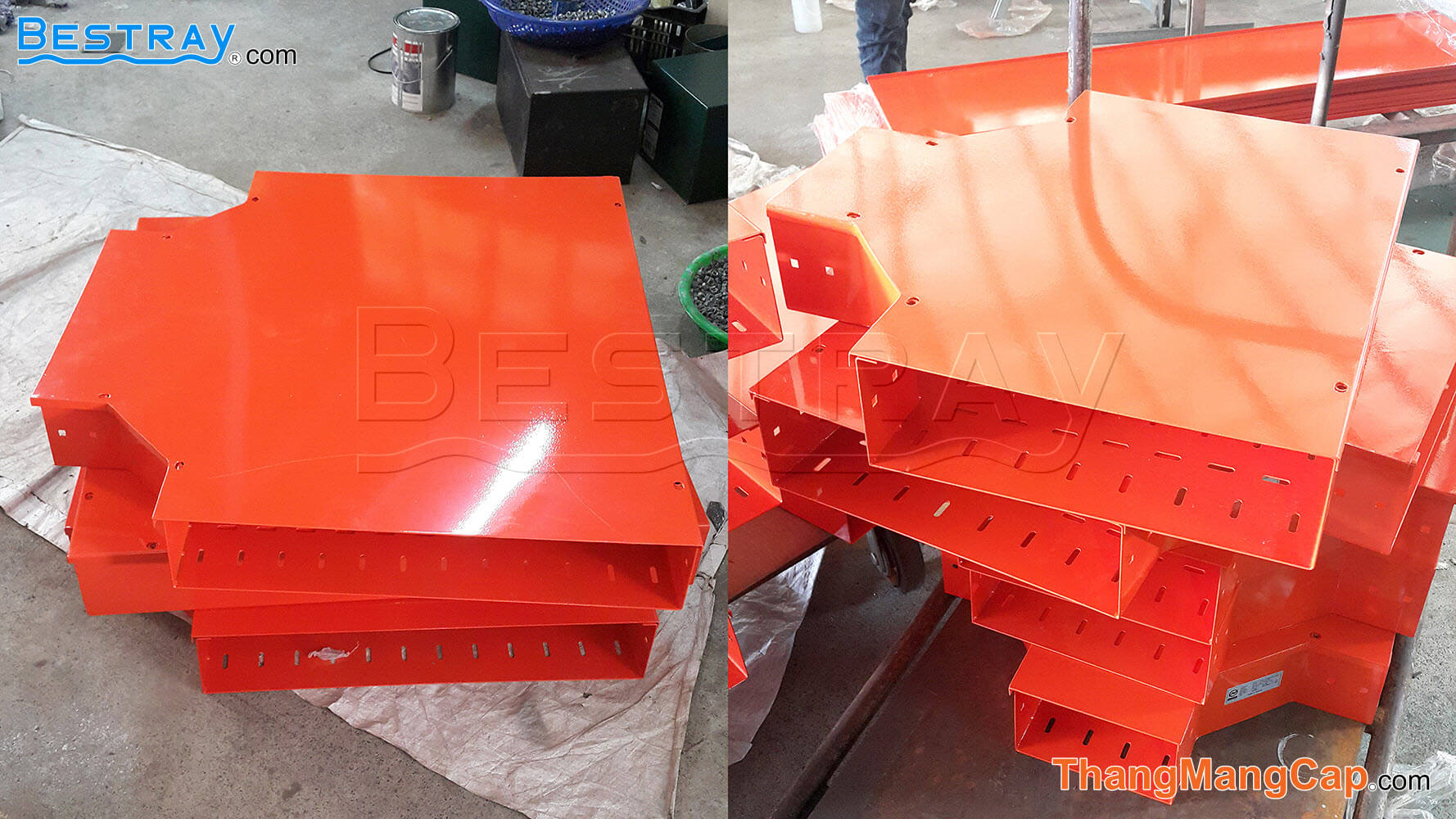

● Powder-coated cable tray cover: this is a material with affordable price, widely used, and anti-rust. The lid is usually made of corrugated iron and then the surface is treated with electrostatic paint. Therefore, the paint layer is adhered to the surface to help prevent impacts from the outside environment. They are widely used in buildings, corridors, or vertical shafts. In addition, the color of cable trays is also used to mark and distinguish cable routes, classify cable systems, etc. in constructions.

● Stainless steel cable tray cover: with stainless steel materials, it has the characteristics of not being rusty, anti-corrosion, and high durability. They are generally suitable for use in a variety of environments.

3.3. Bracket (A supporting mechanism):

In IEC 61537:2006, Section 3.7 defines a “support device” as “a system component designed to provide mechanical support and to be able to limit movement of the running track cable”

In constructions, the rack is a part of the construction process that supports the cable tray ladder system. They play the role of connecting and shaping the components of cable ladders and electrical trays together.

The racks in the cable tray ladder system include:

● Support bar: used to support the cable ladder on the concrete ceiling.

● V hole: used to support ladders, troughs, cable trays with two threaded ends.

● Cable tray ladder rack – Eke: used to support ladders, troughs, trays close to the wall.

● End Cap: Used to seal the waiting end of cable trays and cable trays.

● Wall-mounted cable tray support arm: used to fix, support trays, cable ladders when running close to the wall.

● Support legs: used to support the cable tray ladder system a fixed distance from the floor.

● Perforated multi-purpose support bar (U-bar, C-bar): is specialized equipment for making racks for cable tray ladder systems, hanging pipes at construction sites. Accessories are attached with bolts and screws for quick assembly with tools.

● Non-perforated multi-purpose support bar: made from galvanized steel, powder-coated steel with a thickness of about 2.0 – 2.5mm. The product is designed to be flexible, very simple to install and remove, without any welding, and can withstand the large weight of the project.

3.4. Clamp

● Clamp cable tray product line in the list of accessories cable tray. The device is used to help fix cable trays and supports and concrete floors.They help the cable tray system become safe, limit risks and dangers during construction and use. There are two types of clamps: fixed double clamp and fixed single clamp.

● Cable Ladder Clamp: The main use is to fix the cable tray ladder with perpendicular planes such as walls, concrete floors, U-bars,… The product helps to strengthen the cable tray ladder system without being damaged. Unexpected displacement, warping, edge distortion.

● Pipe Hanger: used to connect pipes to pipe rack assemblies to ensure fastening of cable lines and electrical installation pipelines. Hangers are usually made of 304 stainless steel, 316 stainless steel, or galvanized steel with good corrosion resistance.

● Clamp bowl (Clamp): is responsible for fixing the cable ladder to the concrete floor, bracket, or V hole,… The size of the clamping bowl depends on the size of the cable tray..

3.5. Others

Horizontal cable tray is the accessory is used for buildings, condominiums, factories, apartment buildings, co… The main function of the cable tray is to redirect the path of the cable tray based on the design of the building.

● Upward contraction (abdominal contraction, internal contraction): is an accessory used to redirect the cable ladder system perpendicular to the original plane and perform in an upward direction.

● Downward (backward, outer contraction): This is the same accessory to redirect the cable ladder system perpendicular to the original plane and work in the downward direction.

● Horizontal (L contraction): this type of accessory has the effect of quickly redirecting the cable ladder system in a perpendicular direction on the same plane.

● Horizontal (T contraction) this accessory divides the trough system into three directions on the same plane.

● The horizontal junction (Cross) is responsible for dividing the trough system into four directions on the same plane..

3.6. Hanging

Cable trays also have the same function as a bracket. They have the effect of supporting the cable tray system to be fixed firmly and safely at height. Currently, there are three popular types of hangers as follows:

● Hanging: has the function to hang ladders, troughs, cable trays to the ceiling, factories, high-rise buildings, apartments…

● Optical hangers cable trays: used to hang cable trays, this type is commonly used with small cable trays because they only use 1 thread to hang up.

● Support for hanging ladders, troughs, cable trays: used to hang ladders, troughs, cable trays when installing cable tray systems on the ceiling. This device uses a hanging arm instead of a screw and a V support system.

4. Standard installation accessories

National standard TCVN 9208:2012 (replacing standard TCXDVN 263:2002) of the Ministry of Science and Technology has regulations on standards for installing cable tray accessories for cable tray ladder systems as follows:

● For places where cable trays are installed. If necessary, cable tray and ladder system must be installed together with cable tray shrink, cable tray connection, horizontal numbness, cross-stitch, shrink stitch, tray cover, and other cable tray accessories.

● The cable tray or ladder is not > 1200mm wide, there must be a bracket or optical hanger after each distance of 1m – 3m. At the same time, this distance must be approved by the competent authority before construction.

● The tray top cover, cable ladder, and additional means of protection must be easily removable.

● The locations of hangers and brackets must be carefully marked to conform to approved original specifications.

● Brackets, optical hangers must be fixed to the building structures or welded to the steel codes implanted in the concrete structure of the ceiling.

● Each cable tray or ladder must be in an elastic position on supports or slings.

● Locations where cables from within a cable tray/ladder enter a conduit or other means of enclosure, sturdy support should be provided to prevent strain from being applied to the cable.

● Before installing the tray, the cable ladder and accompanying accessories need to be thoroughly checked to make sure there are no electrical or mechanical problems.

5. Manufacturing and installing cable tray accessories at Bestray

5.1 Manufacturing and installing cable tray accessories at Bestray

Bestray owns a factory with a completely closed process, spacious material storage space, and meets high safety and quality standards. Along with a system of modern and automated machinery, imported from abroad, the production line meets international standards. Besides, the high performance of the machine ensures to meet a large number of orders according to the requirements of customers.

● Selection of materials: all products are made from materials of corrugated iron, stainless steel, aluminum,… depending on the requirements given to us by the customer. At the same time, the product is manufactured with a standard metal thickness from 1.0mm to 2.0mm.

● Choose the size and design suitable for the cable tray system. Bestray cable tray accessories avoid the collision of systems in houses and factories when installing.

● Products help reduce costs with the best price for customers. Ensure relatively high aesthetics, variety of models, and sizes to match the cable tray system of many projects.

Our company is trusted by many projects and is widely known for its cable tray accessories made of the best stainless steel and galvanized iron. Every product will be thoroughly tested and validated before being put on the market. The devices are anti-corrosion and have great tensile strength. We manufacture these accessories to standard as well as custom designs.

5.2 The installation process of cable tray accessories:

Each different construction project will have a different cable tray system. A thorough understanding of the general installation process of the cable tray ladder system is essential to ensure the progress of the project. The following are 7 important steps when installing cable tray accessories for the project:

Step 1:

Determine the power chute routes according to the construction drawings of the project. Next, determine the dimensions from the reference shaft to the installation site. Then, mark the mounting position of the route control chute details (angle, end, branch) and route size according to the detailed reality (up/down, branching, redirecting,…. ). From there, determine the points to hang the chute and where to drill or create technical holes in the structure.

Step 2:

Carry out drilling or welding operations on the structure to install expansion bolts and mount hangers or brackets at the marked position. At the same time, make sure the chute line is straight and oriented according to the predetermined axes. Then, drill or punch holes through the structure at the predetermined positions and. Treat the hole by surfacing, smoothing, or buffing.

Step 3:

Install the cable tray on the installed supports and according to the design with the order: install the terminal, corner, and branch details first and then install the straight segments connecting these details. Note: with straight sections, the steel edge of the cut must be ground or painted before continuing to connect the next chute to the pre-assembled cable tray.

Step 4:

Connect equipotential wires at cable tray joints required by customers. Next, install barriers, support structures, and insert gaps at positions through the building structure by the specifications.

Step 5:

Check and complete the installed cable tray system: elevation, order of trough layers, distance between layers and standard axis, horizontal or vertical and solid axis, no deformed… Besides, check, add and tighten the bolts connecting the cable tray. To ensure safety, it is recommended to remove the sharp edges of the trough edge, the cuts and paint those locations.

Step 6:

Check and mark the completed gutter route on the construction drawing of the project. In addition, it is necessary to consult the inspection and acceptance of construction test samples. After that, clean up excess materials, keep the construction area tidy.

Step 7:

After all cable pulling work is completed, continue to check and repair cable trays if they are deviated due to construction, and then install the cable tray cover.

6. Company introduction

Bestray has always been a reputable address specializing in manufacturing and supplying cable tray ladders with high quality standards in the market. With more than 15 years of experience accumulated during our operation, we hope to bring customers the best product lines.

Our cable tray accessories are highly appreciated for their designs, designs and reasonable prices. At the same time, Bestray has a team of professional, dedicated, senior employees and modern technology machinery to always bring perfection to your project.

Bestray always brings a price list of cable tray accessories which is provided fully, clearly, without intermediaries and at a price suitable for your project. For more product information or advice, please contact us today.

Besides, customers can also learn more about other products such as cable trays, cable trays, accessories of cable trays that Bestray currently supplies.

If you want more detailed information, please feel free to contact us.

Bestray JSC

Address: 180/7A, Tan Thoi 3 Hamlet, Tan Hiep Commune, Hoc Mon District, Ho Chi Minh City

Open at 7:30 – close at 17:00

Phone: 0909 089 678

Email:

info@bestray.com

sales@bestray.com