For the cable tray ladder system to be installed easily, safely, and with high aesthetics. In addition to the main products such as cable ladders, cable trunking, or cable trays, other accessories are also important factors. In particular, for the system to be sturdy and easy to install in many different terrains and surfaces, the support of cable ladder racks is needed.

1. What is a cable bracket?

Support Devices or Support Devices according to IEC 61537:2006, Section 3.7, are defined as follows: a system component designed to provide mechanical support and to be able to restrict movement of the cable run.

Cable tray ladder holder is a kind of installation accessory of cable tray ladder. It has the function of supporting and fixing the cable tray ladder system. Help the cable tray ladder system become firm, safe and limit risks during construction, installation, and use.

In addition to the bracket, when installing the cable tray ladder system, there are other types of accessories. You can check out more Bestray products here.

2. When to use cable ladder bracket?

Bracket accessories are commonly used in the following cases:

• Used in buildings, apartment buildings, factories, factories,…, supporting cable ladders, cable trays, overhead cable trays, Large size, mainly wall-mounted, column-mounted, ceiling-mounted, frame-mounted.

• Installed in large projects, with complex wiring and wiring systems and invested in technology and equipment

3. Advantages of using bracket

The bracket is a widely used accessory when installing cable tray ladder systems in buildings, apartment buildings, factories, factories,… because it offers the following advantages:

• Supports the system. The cable tray ladder system is installed safely and used for a long time. Makes system installation easier.

• Support to support the cable tray ladder system, creating certainty.

• Increased use of space.

• There are different types of brackets to suit all installation situations of cable tray systems.

• Helps the wiring and conductors to work better, avoiding external factors that cause bad effects.

• Increase the aesthetics when installing the system.

With the above advantages, the rack has become an important accessory when designing and installing the cable tray ladder system.

4. Types of brackets

Currently, to ensure the installation and use of the cable tray ladder system is sure and has good bearing capacity. Depending on each case, different types of cable ladder brackets will be used. Here are a few types of brackets that are commonly used on the market today

4.1. Type U

U-brackets are a popular product line. It is used in case the cable tray ladder system needs to go close to the wall. At this point, the bracket will be drilled into the wall at a 90-degree angle. Then simply attach the cable tray ladder to the bracket and secure it together with screws.

4.2. Hanging sloping ceiling

In the case of sloping ceiling areas, the most commonly used product to support the cable tray system is a sloping ceiling mount. It helps that the cable tray ladder system can be clad close to the ceiling, increasing the usable area and increasing the aesthetics. This type of rack accessory is designed to fit into the ceiling and form a flat shelf. At this time, the cable tray will be guaranteed to be contained on the surface.

4.3. Cable tray ladder hanging frame

For the cable tray ladder system along with the ceiling, the most commonly used product is the cable tray ladder frame. This type of rack is designed differently depending on the requirements of use, including:

• Cable tray ladder hanging frame

• Cable tray ladder hanging frame with spacers

• Cable tray ladder hanging frame with 2-prong spacers

• Trough ladder hanging frame cable tray with symmetrical detachable end

• Hanging bracket for cable tray ladder with detachable end asymmetrically

• Hanging frame for cable tray ladder with detachable end

• Horizontal beam for ceiling panel of cable tray ladder

4.4. Wall mounts

Another type of bracket is used to attach parallel to the wall, to fix and bear the load for the cable tray ladder system, called the cable tray ladder support wall bar. Just like cable tray ladder brackets, wall rails are also available in different types such as:

• Wall mounts

• Sloping wall mounts

• Wall mount brackets with spacers

• Wall mount brackets.

4.5. Navigation frame

For the cable tray ladder system, during the installation and use of the diversion rod, you need to use a redirecting frame. Two types of navigation frames are used a lot:

• Wall-mounted navigation brackets

• Steel-mounting brackets

Depending on the different installation locations, you can use different types of bracket accessories to suit your needs. suitable for safety and convenience.

5. Bracket Specifications

Cable ladder bracket accessories have several important specifications such as:

• 4 oval holes punched on the part in contact with the wall

• 5 – 7cm longer than the cable ladder, cable tray, cable tray

• The part in contact with the ladder The cable tray is punched with 2 oval holes to prevent it from moving

• The size of the bracket is usually large and wide to create stability

• The thickness of the bracket is usually 2.0mm ~ 5.0mm

• Depending on the requirements, the bracket will be painted electrostatic, electrolytic galvanizing, hot dipping galvanizing, ZAM corrugated iron,…

• The holder shape is simple and easy to produce in large quantities.

6. Bracket quote

When choosing a cable ladder bracket supplier, the first thing that customers need to pay attention to is product quality. Because only good and high-quality products are guaranteed to be safe during installation and use. At the same time, they also ensure the system is used and works well in the long run.

Besides, an equally important factor is the cost of cable ladder racks. Carefully choosing a supplier of rack accessories will help you a lot in both getting a good product and saving a lot of money. To know more about the cost of bracket accessories, you can see more here

7. Bracket Production line

Bestray cable ladder brackets are made according to standard procedures to ensure the best quality products.

Step 1: Calculation of SWL load, size of cable ladder rack

Before starting production, SWL load and size of cable ladder rack need to be carefully calculated to ensure compliance with project technical requirements. . All types of racks must be designed and tested for SWL loads according to IEC 61537:2006 in Section 10.8. Thanks to that, the rack accessory will play its role well for the system. At the same time, it helps to make the installation process convenient and safe during use.

Step 2: Choose the type of rack, the material of the rack

Cable ladder racks have many different types such as U-racks, sloping ceiling hangers, cable tray ladder brackets, cable ladder support wall bars, navigation frames. Depending on the location, different types of rack accessories will be selected.

Besides, depending on the environmental conditions, the mounting accessories also need to be selected with the appropriate materials and surface treatment. Some commonly used materials include powder coating, electrolytic galvanizing, hot-dip galvanizing, ZAM corrugated iron, etc.

In addition, before production, it is also necessary to carefully calculate the parameters. specifications for the length, width, and thickness of the fittings.

Step 3: Cut the workpiece according to the technical drawing

Based on the calculated technical drawings, workers will cut the workpiece. After cutting, the sheet needs to be accurate in size, smooth, not rusty, warped.

Step 4: Punching processing

The corrugated iron sheets will, after being cut, be put into the CNC machine and punched according to the design. Bracket accessories need to be accurate, make the installation process go smoothly, and have high aesthetics.

Step 5 Forming the product

After punching the hole, the product will continue to be transferred to the folding press according to the shape and structure of the rack that has been determined and designed before.

Step 6: Check the product before painting

Cable ladder support accessories will be carefully checked to ensure that the specifications are accurate compared to the drawings in terms of thickness, length, width, quantity. After meeting the requirements, the product will be transferred to the surface treatment step.

Step 7: Surface treatment

The rack will be cleaned according to standards to ensure that the finished product will have a durable and beautiful coating. After cleaning, the product will be painted in the color required by the customer.

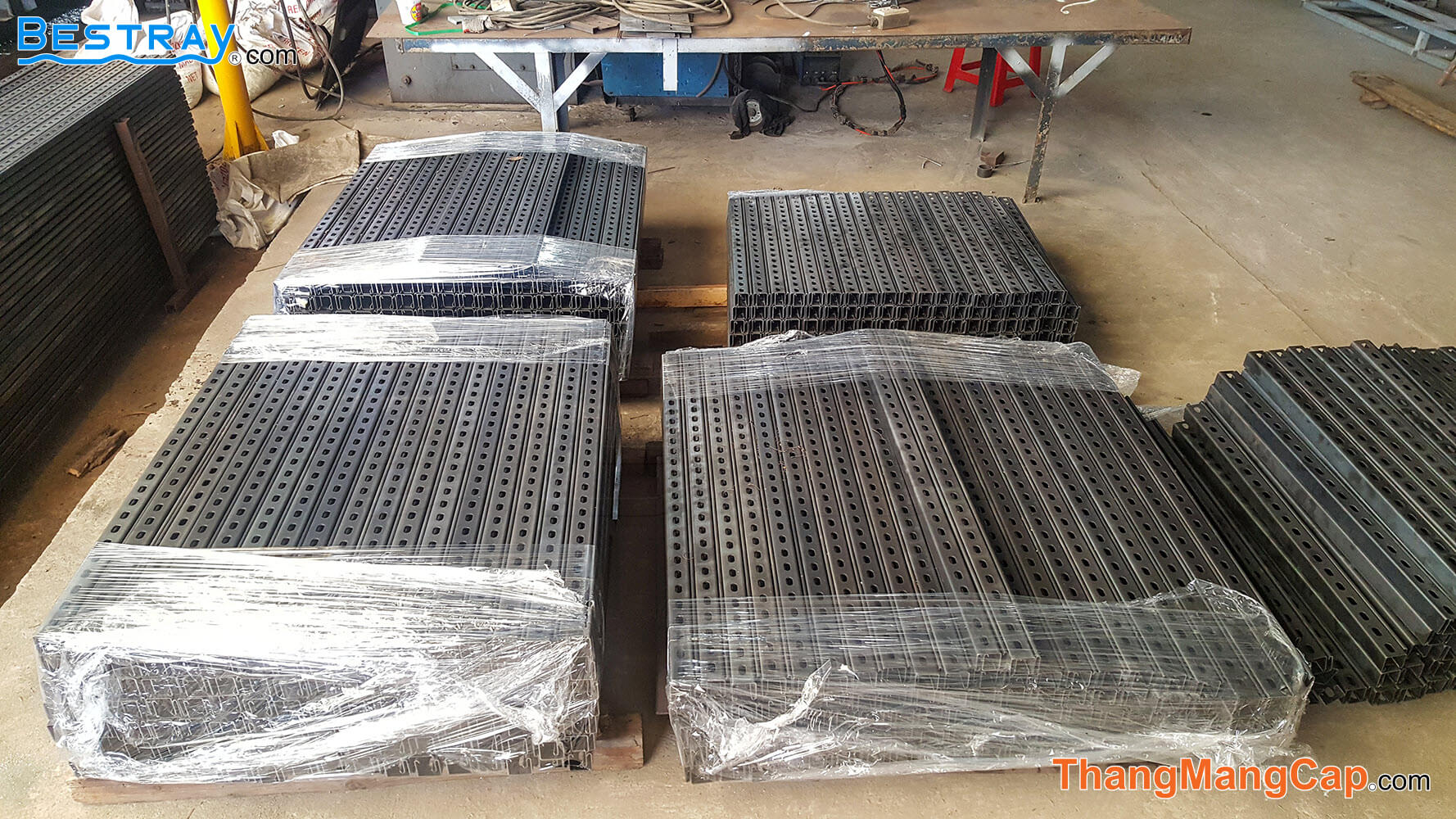

Step 8: Checking, packing, and handing over to customers

The last step in the production process of cable ladder racks is to check product quality. Brackets need to ensure enough quantity and correct size with the data of the technical drawing. The product must have a firm texture, an even and smooth coating.

Once the inspection is completed, the product will be carefully packed and returned to the customer.

8. Company introduction

In the market, there are many manufacturers, providing cable tray ladders and attached accessories to meet the increasing demand for use in buildings, factories, high-rise apartments,… It is difficult for customers to distinguish between high-quality goods and poor-quality goods. Therefore, you should choose reputable places, be committed to quality, and have clear documents to buy. Bestray is a manufacturer, supplier, and distributor of cable trays and accessories, gaining the trust of the works for many years.

We supply all kinds of cable tray accessories in various shapes. The product can be used to connect the main cable tray, install it on the ceiling, wall, and other places. Various accessories can ensure the stability and flexibility of the cable tray.

Bestray is a reputable unit specializing in manufacturing, supplying, and distributing connecting accessories, racks, and hanging safety cable trays – high-quality international standards. Besides, the price list of cable trays and accessories is always fully and continuously updated by us, customers can refer to it here (leading to the quotation page). We always provide customers with reasonable prices, without intermediaries, and provide full information about products to customers.

If you have a need to use Bestray’s cable trays, cable ladders, and accessories, please contact us according to the information below for support, advice, and detailed product quotes.

Find out more cable tray accessories:

If you want more detailed information, please feel free to contact us.

Bestray JSC

Address: 180/7A, Tan Thoi 3 Hamlet, Tan Hiep Commune, Hoc Mon District, Ho Chi Minh City

Open at 7:30 – close at 17:00

Phone: 0909 089 678

Email:

info@bestray.com

sales@bestray.com