Cable trays play an important role in ensuring the safety of electrical wiring, cables, etc. to work at their best. Currently, the use of cable trays in factories, buildings, and apartment buildings has become very popular. This is considered a system to help protect wires and cables and easily replace them if necessary. As a result, their service life is also longer and they are protected from incidents and environmental factors. In the article below, Bestray will provide additional information necessary for you to better understand the cable tray.

1. What is a cable tray?

The English name of the cable tray is “Perforated Cable Tray” or “Cable Tray”. It is intended as a system for supporting, installing, and protecting cables, power distribution conductors, insulating products, and communication signal cables.

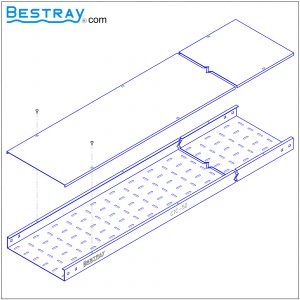

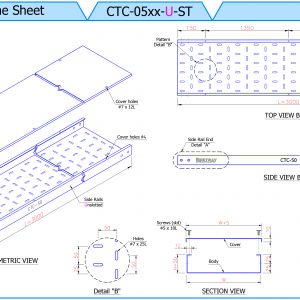

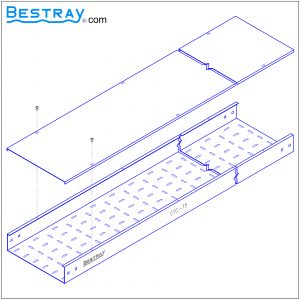

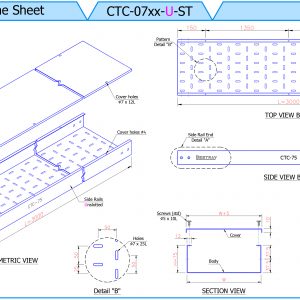

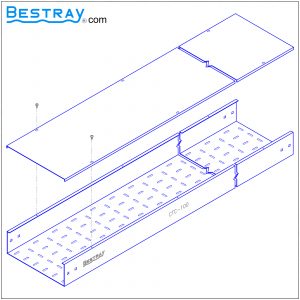

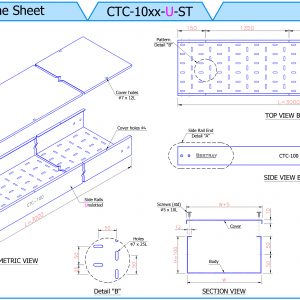

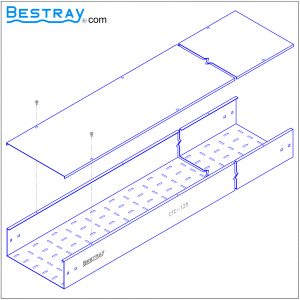

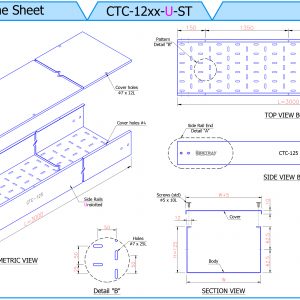

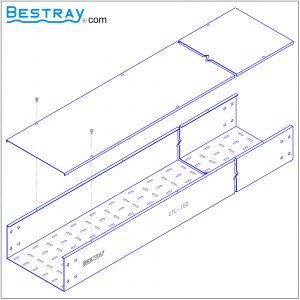

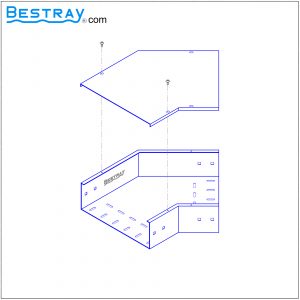

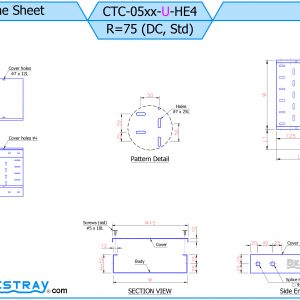

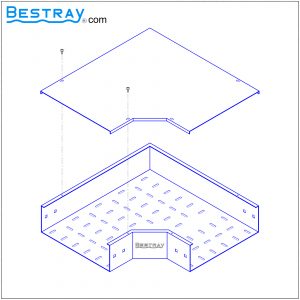

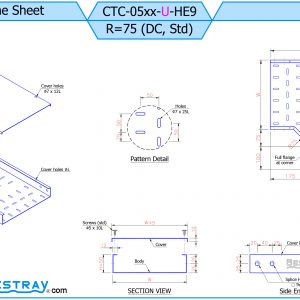

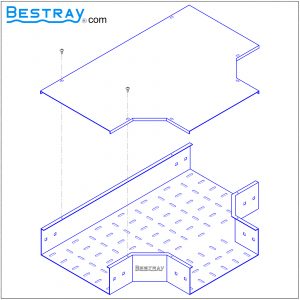

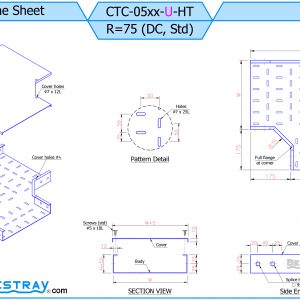

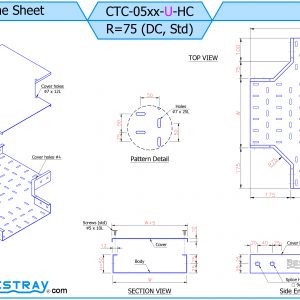

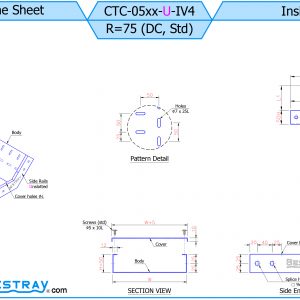

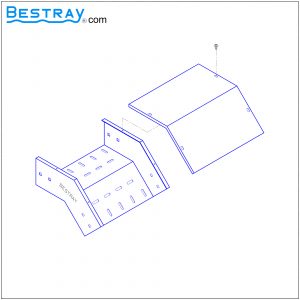

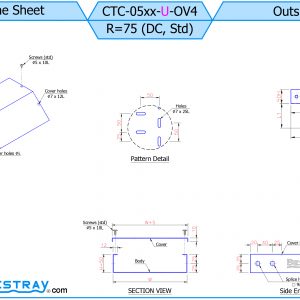

The cable tray is designed in the shape of a rectangular box with a hole punched above it. Their function and to fix various types of conductors. Currently, buildings, apartment buildings, factories, etc. are often equipped with cable tray systems. Thanks to that, the process of installing, dismantling, and replacing the system is also made easier.

2. Difference between a cable tray and cable trunking

Cable trays and cable trunkings are two frequently confused products on the market. The main reason is that their design is relatively similar. However, when you look closely, you can still easily recognize the differences between cable trays and cable trunking in terms of structure and features.

Structure:

- Same: Both cable trays and cable trunkings are designed in the shape of a rectangular box and have a cover.

- Various: The cable tray is usually perforated. Therefore, its weight will usually be lighter than the cable trunking. However, it can still be met in terms of efficiency and aesthetics

Features:

Same:

- In terms of features, both cable tray and cable trunking are used to support the arrangement and management of conductors. Thanks to that, external influences will not be able to affect the line. In addition, space and cost are also saved a lot, bringing a higher aesthetic than using conduit.

Different:

- Conductors with sizes from 1.5 - 95mm2 with a plastic sheath made from PVC usually use cable trunkings. They are often used in environments with high requirements for cleanliness because the lids form a completely sealed container. Therefore, many people choose cable trunkings to install with closed circuits when wiring on the ceiling because they rarely have to open the cover.

- Meanwhile, for wires with a size of 50mm2 or more with a plastic sheath made from PVC, cable trays are often used. To increase electrical conductivity as well as heat dissipation, this conductor is designed with only one layer. The cable tray is designed with perforated holes, so heat and water drainage are also increased.

- Besides, it is much more convenient to repair or add or remove wires in the box because the cable tray rarely uses a tight cover. Therefore, cable trays are often used in high-temperature projects that require heat dissipation or low-humidity environments.

3. When to use cable trays

Usually, people often use cable trays to install wiring and cable systems in apartments, buildings, production facilities,... The function of cable trays is to protect traditional signal cables or power distribution cables.

In industrial and commercial construction, cable trays are often installed to aid in system management. Especially, if you want to change the wiring, this installation is very convenient and useful. Because now, instead of having to install through a pipe, you just need to put the new cable in the cable tray.Powder-coated cable trunking

4. Cable tray manufacturing materials

Cable trays are manufactured from many different materials such as:

- Black corrugated iron cable tray has been painted with an electrostatic layer. It is often used in dry places such as indoors and does not have to be exposed to chemicals.

- Hot dipped galvanized corrugated iron cable tray is used in an outdoor environment, has high corrosion resistance.

- Stainless steel cable trays 201, 304, 316 have high aesthetics and durability.

- The galvanized cable tray is made from durable steel. It has anti-oxidation, anti-corrosion, anti-rust ability, so it is very suitable for use in outdoor works.

- Composite cable tray has very good corrosion resistance. Therefore, it is suitable for use in areas with salinity, near the sea, or in environments exposed to chemicals.

5. Cable tray standards

Some standard features of cable trays include:

- Materials of manufacture: Black corrugated iron with an electrostatic coating, galvanized corrugated iron, hot-dipped galvanized corrugated iron, Stainless steel 201, Stainless steel 304. , Stainless steel 316.

- Standard length: 2.4m, 2.5m, or 3m

- Standard width: 50 ÷ 800mm

- Standard height: 40 ÷ 200mm

- Standard thickness: 0.8mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

- Popular colors: White, orange, wrinkle cream, or depending on customer's request.

6. Cable tray manufacturing process

The cable tray manufacturing process at Bestray is carried out according to a system to ensure customers receive the best products.

Step 1: Receive and learn about customers' needs

For customers to get the most satisfactory products, the first step before producing cable trays that Bestray cares about is to understand the purpose and needs of using the product. Products. From there, we will easily calculate the appropriate product size and material.

To increase the use time and increase the durability of the cable tray, we will conduct an actual survey and make accurate measurements.

Step 2: Select the appropriate cable tray material

Depending on the environmental conditions, we will advise on the appropriate cable tray material. Some of the most commonly used materials include:

- Powder-coated black corrugated iron

- Hot dipped galvanized sheet Inox

- In addition, having design drawings for the product also need other technical parameters such as length, width, detailed thickness.

Step 3: Cut to the specified size

In this step, Bestray will proceed to cut the sheet metal according to the size of the previously determined cable tray. Materials for making cable trays must have a satisfactory thickness, ensure quality, not rust, warp.

Step 4: Punching processing

Depending on the designed drawings, the product will be punched as required. Bestray uses CNC technology, which is a modern technology with high accuracy and aesthetics. As a result, the product always achieves the best quality.

Step 5: Shaping the product

After punching the hole, the product will be transferred to the press. The parameters of scale and size have been set up before. As a result, the cable tray will be quickly bent, welded, and firmly shaped,

Step 6: Check the surface, treat before painting

After processing the rough product, it is necessary to check the details of the joints, weld thoroughly. At the same time, technical parameters such as length, width, and length also need to be checked for accuracy. After meeting the requirements, the surface treatment will be carried out on the raw product.

Step 7: Clean, wash, paint and dry the surface

The raw product will be thoroughly cleaned according to the standard depending on the surface coating technology. To ensure that the finished cable tray has a beautiful and durable coating over time, this is a very important step.

After the cleaning is complete, the cable tray will be painted with a surface coating according to the customer's requirements.

Step 8: Check, pack and deliver products to customers

After finishing, the cable tray will be inspected for the last time. This step is to make sure the cable tray has a solid structure, is the right size, is not distorted, warped, has high aesthetics, and meets the requirements of the customer. The cable tray will then be carefully packed and shipped to the customer's address.

7. Company introduction

Bestray Joint Stock Company with more than 15 years of experience specializes in consulting, manufacturing, trading, and service in the electrical industry. We are trusted by many investors, construction companies, electrical works, and high-rise apartments. And has become the leading professional manufacturer and supplier of cable tray ladders, mesh trays all over the country.

To avoid buying low-quality products, you should choose reputable places, be committed to quality, and have verification documents. Bestray is a reliable manufacturer and supplier of cable trays and accessories for many years. We bring to customers products that are reputable, reasonably priced, in accordance with international standards, and contribute to creating sustainable construction values.

The price list of cable trays on the market with other units does not have a big difference. However, depending on the type of product that the customer chooses, the price of the product may fluctuate. Bestray Joint Stock Company always gives customers quality products and clear, detailed product quotes, and most reasonable prices. Click here for more information and products of our cable tray price list.

Besides, customers can also learn more about other products such as cable trays, cable ladder, accessories of cable trays that Bestray currently supplies.

If you want more detailed information, please feel free to contact us.

Bestray JSC

Address: 180/7A, Tan Thoi 3 Hamlet, Tan Hiep Commune, Hoc Mon District, Ho Chi Minh City

Open at 7:30 - close at 17:00

Phone: 0909 089 678

Email:

info@bestray.com

sales@bestray.com