Post-paintability

Results of corrosion tests of painted materials

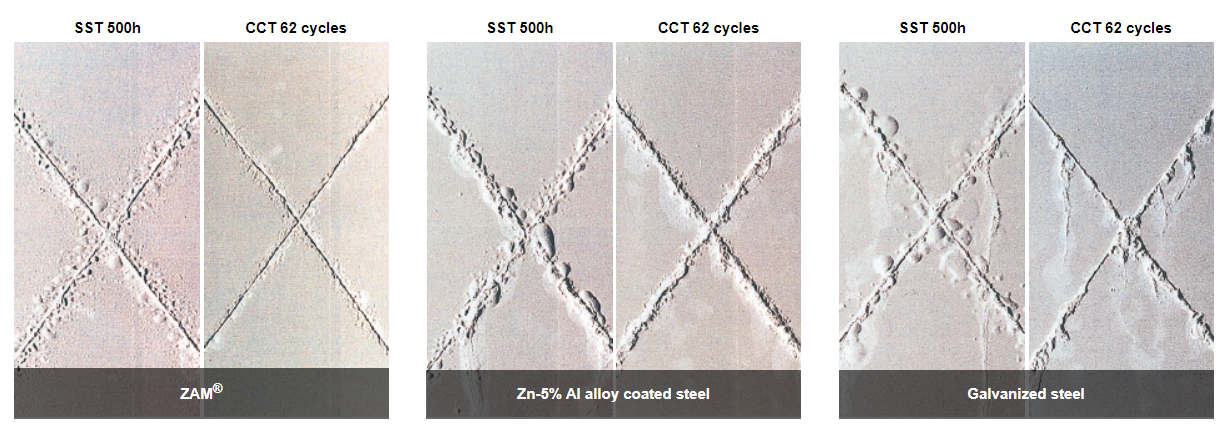

ZAM® is superior to other coated steel sheets in terms of corrosion resistance after painting.

Appearances of coated materials after corrosion test (cross cut sections)

Precautions

Precautions

- 1. As with Hot-dip Zn-5%Al alloy coated, it is recommended to control the concentrations of treatment solutions because aluminum contained in the coating layer dissolves into pre-treatment (zinc phosphate treatment) solutions and lessens their effects.

- 2. The above painting data is an example. It is recommended that each customer test and check the paintability beforehand.

- 3. When chemically-treated substrate is used, application of adequate primer is recommended.

Test conditions

- ① SST: JIS Z2371 (neutral salt spray test) 35°C, continuous spraying with 5% NaCl

- ② CCT: JASO M609-91 (combined-cycle corrosion test)

SST (2 hrs) → Drying (4 hrs) → BBT (2 hrs) - Material tested: Untreated material of each coated steel sheet

Pre-treatment: Zinc phosphate treatment (PALBOND 138)

Paint: Acrylic resin Super Lac F-50 Film thickness: 30 μm

Source: Nippon Steel