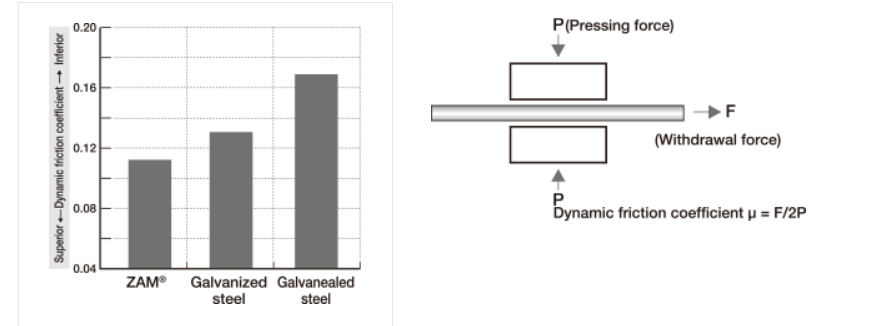

Sliding characteristics – Workability

Sliding characteristics

Having a coating layer with high surface hardness and smoothness, ZAM® exhibits superior sliding characteristics.

Dynamic friction coefficients of various types of coated steel

Sliding test conditions

| Sample size | 0.8 mm (thickness) x 30 mm(width) x 300 mm (length) |

| Press oil | Z5 (Idemitsu Kosan) |

| Pressing pressure | 0.72、1.45、2.90N/mm2 |

| Pressing force | 1、2、4kN |

| Pressing area | 46×30mm2 |

| Withdrawal rate | 1000mm/min |

| Mold surface roughness | #1000 (Polishing for each session) |

| Mold material | SKD11 |

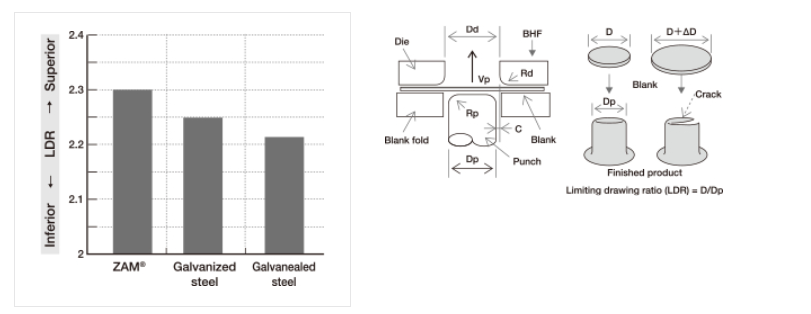

Workability

ZAM® has better drawing characteristics than other types of coated steel sheets.

Limiting drawing ratios (LDRs) of various types of coated steel sheets

Conditions for deep drawing test

| Diameter of punch (Dp) | 40mm |

| Diameter of die (Dd) | 42mm |

| Shoulder radius of punch (Rp) | 5mm |

| Shoulder radius of die (Rd) | 5mm |

| Stroke speed (Vp) | 60mm/min |

| Press forming oil | Z5 (Idemitsu Kosan) |

Samples

| Coating mass | Material | Post-treatment | |

|---|---|---|---|

| ZAM® | 70/70 g/m2 | Deep drawing quality | ZC treatment |

| Galvanized steel | 60/60 g/m2 | Deep drawing quality | ZC treatment |

| Galvanealed steel | 45/45 g/m2 | Deep drawing quality | ZC treatment |

Nguồn: Nippon Steel