Comparison of properties with various types of coated steel sheets

Comparison of properties with various types of coated steel sheets

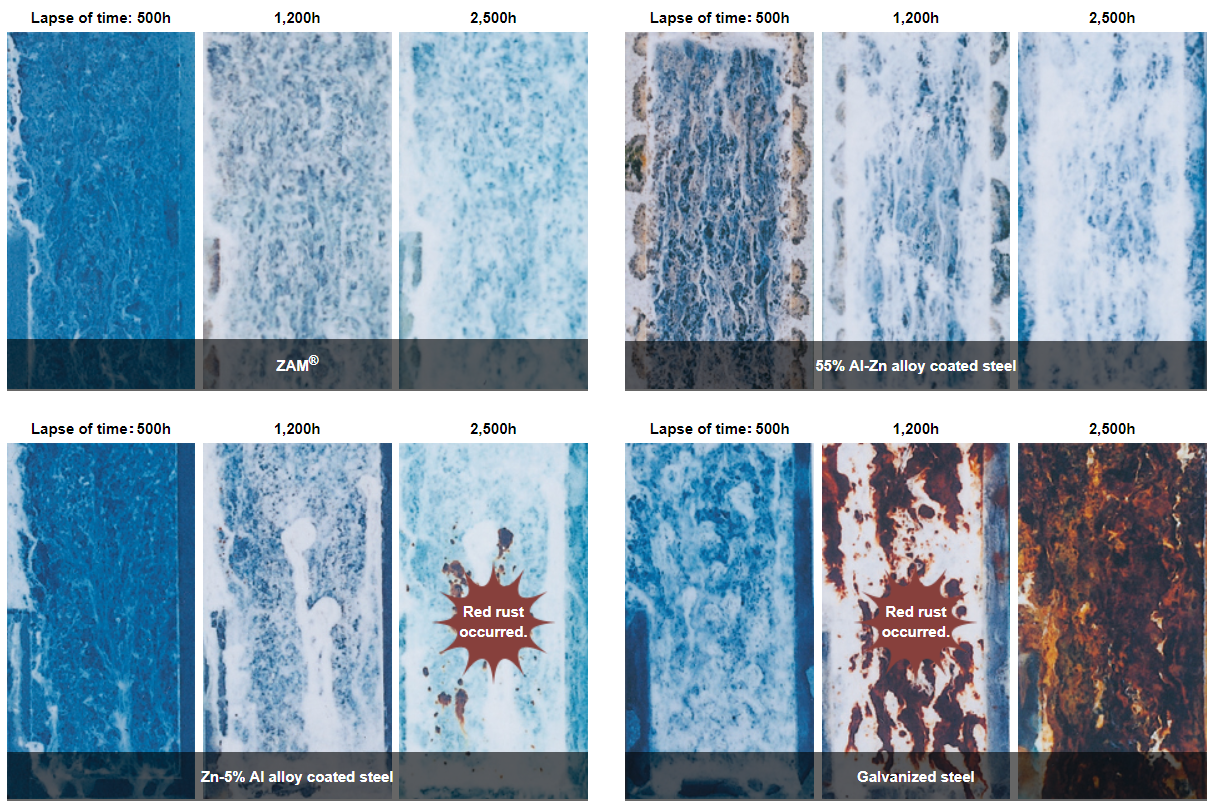

Corrosion resistance on flat parts

ZAM has better resistance to red rust than galvanized and hot-dip zinc-5% aluminum alloy coated steel sheets

Results of salt spray test (SST: JIS Z 2371) Appearances of specimens after salt spray test

(Coating weight: 90/90 g/m2, untreated)

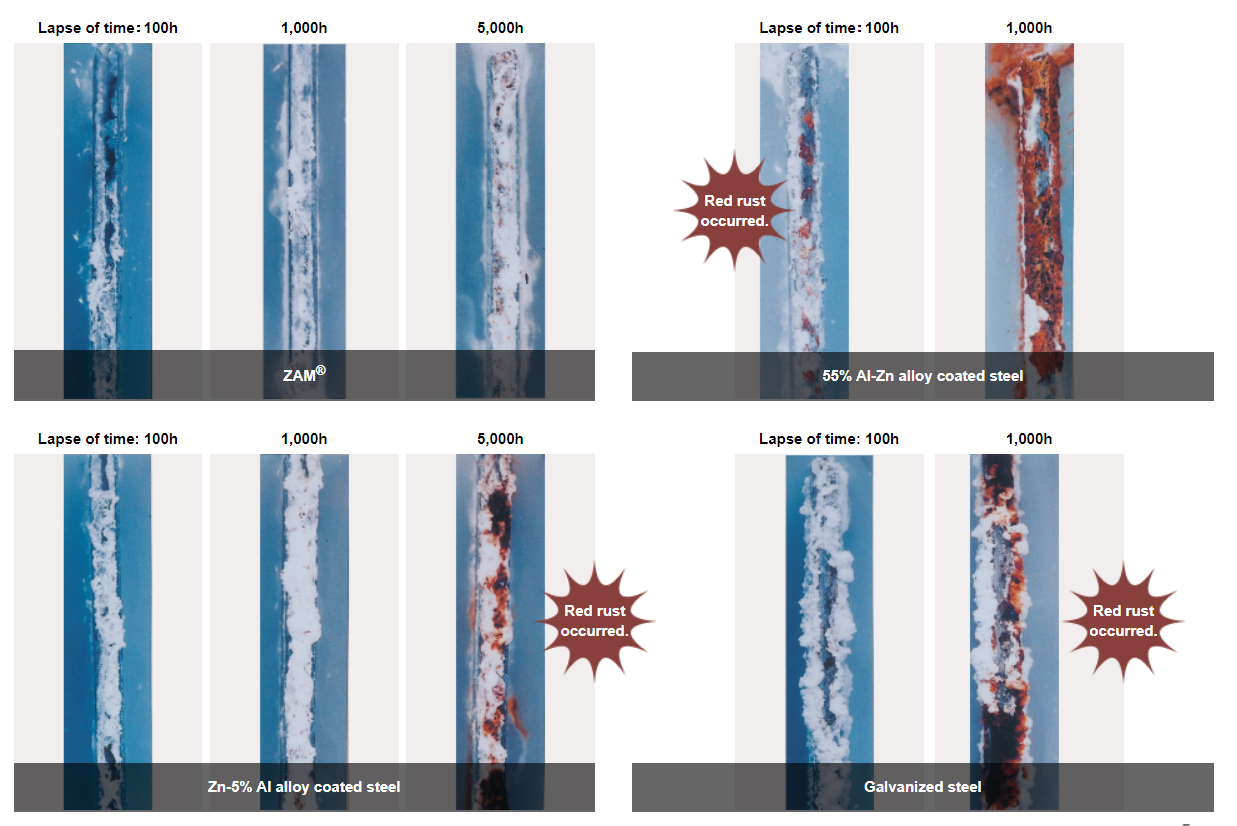

Corrosion resistance on cut edge

ZAM® shows better red-rust resistance (durability) on cut edge than any other coated steel sheet.

Appearances of cut edges after salt spray test

(Thickness: 3.2 mm, coating weight: 120/120 g/m2, untreated)

Change in the appearance of cut edge during outdoor exposure test

The cut edge of ZAM® will be covered with a protective film and change to a subdued color as time passes.

Appearances of cut edge sections after outdoor exposure test (testing location: seaside industrial area in Sakai)

(Thickness: 2.3 mm, coating weight: 90/90 g/m2, chromate treatment: 50 mg/m2)

Corrosion resistance of bent sections

Appearances of 1t bent section after salt spray test

(1t, 180º bending, thickness: 3.2 mm, 120/120 g/m2, untreated)

Change in appearance at bent section during outdoor exposure test

Corrosion resistance of drawn sections

ZAM® shows better corrosion resistance on drawn parts compared to hot-dip zinc-5% aluminum alloy coated steel sheets.

Appearances of drawn parts after salt spray test

(drawing height: 25 mm, thickness: 0.8 mm, coating weight: 70/70 g/m2, untreated)

Source: Nippon Steel

Source: Nippon Steel